FEATURE

not control design, so mat thickness was not reduced with decreasing

allowable loads. Mat stiffness was required to deliver load to the

piles farther out from the core walls via mat flexure.

Representative unit concrete placement costs of $565 and $335

per cubic yard was used for pile cap concrete and core mat concrete,

respectively. These costs included excavation, shoring, reinforcing

steel, concrete placement and stripping. A summary of pile cap and

core mat concrete volume, total concrete volume and concrete cost

for the various designs is presented in Tables 1a and 1b.

As would be expected, total concrete volume and cost

increased with decreasing allowable loads. A review of Tables

1a and 1b indicates that the difference between the design scenarios

using the highest allowable load with set-up and the lowest

allowable load without set-up amounted to 1,995 cubic yards

of concrete. This results in an extra concrete cost of $935,125

($1,663,925 versus $728,800).

Construction-control method costs

Based on actual costs incurred for the test program, costs associated

with the various CCMs and components were estimated.

Costs incurred by the contractor, the dynamic testing agency and

the geotechnical engineer were included. Distinction was made

between dynamic load testing during installation (performed for

designs both with and without set-up) and during restrike testing

(performed only for designs with set-up). Distinction was also

made between a static load test instrumented to provide loadtransfer

behavior (performed for designs with set-up) and a noninstrumented

static load test (performed for designs without setup).

A summary of CCM costs for the various designs is presented

in Tables 1a and 1b.

As would be expected, construction-control method costs

increased with increasing allowable loads and CCMs which included

field characterization of set-up were more expensive than those

that did not characterize set-up. A review of Tables 1a and 1b indicates

that the CCM cost difference between the design scenarios

using the highest allowable load with set-up and the lowest allowable

load without set-up was $235,760.

Nine of the 10 test piles were installed in production-pile locations.

Based on the production piles’ average embedded length and

unit installation cost, installing nine test piles in production-pile

locations reduced the project’s net test program cost by approximately

$28,000.

Total foundation costs

For each of the design scenarios and their associated allowable pile

loads, total foundation cost was determined by adding the pile,

concrete and construction-control method costs together. The

resulting total foundations costs are presented in Tables 1a and 1b.

A review of Tables 1a and 1b indicates that the total cost difference

between the design scenarios using the highest allowable load

with set-up and the lowest allowable load without set-up results in

a total foundation cost savings of $3,300,912 ($2,513,762 versus

$5,814,673, a factor of 2.3).

Despite increased CCM costs associated with higher allowable

loads, whether incorporating set-up or not, total foundation

costs decreased with increasing allowable loads. Similarly, despite

increased CCM costs associated with characterizing set-up for

a given safety factor, total foundation costs decreased when setup

was incorporated in design. In other words, whether testing

resulted in using a lower safety factor or in incorporating set-up,

the savings resulting from increased testing far exceeded the cost

of the testing.

The relationships between pile cost, concrete cost and the sum

of the two versus allowable load are presented in Figure 1. A review

of Figure 1 indicates that the piles account for approximately 65 to

70 percent of the constructed foundation cost. A review of Figure

1 also indicates that a given increase in allowable pile load from a

lower value results in greater cost savings than a given increase in

allowable load from a higher value. For example, greater savings

are realized by increasing the allowable load from 250 to 350 kips

than from 500 to 600 kips, an allowable load increase of 100 kips

in both cases. This is because at higher allowable loads, a reduction

in pile count at a given cap is less sensitive to an increase in allowable

load. Additionally, at higher allowable loads, more pile caps are

more likely to already contain the minimum required number of

piles (from a structural design standpoint) and still-higher allowable

loads do not result in fewer piles in those caps.

Schedule comparison

Evaluation of potential construction-control method scenarios

needs to include not only economic aspects, but also construction

schedule impacts (which have economic aspects because time is

money). Projects often have a direct correlation between economics

and the construction schedule, such as facilities that generate daily

revenue when brought into service. Less apparent economic aspects

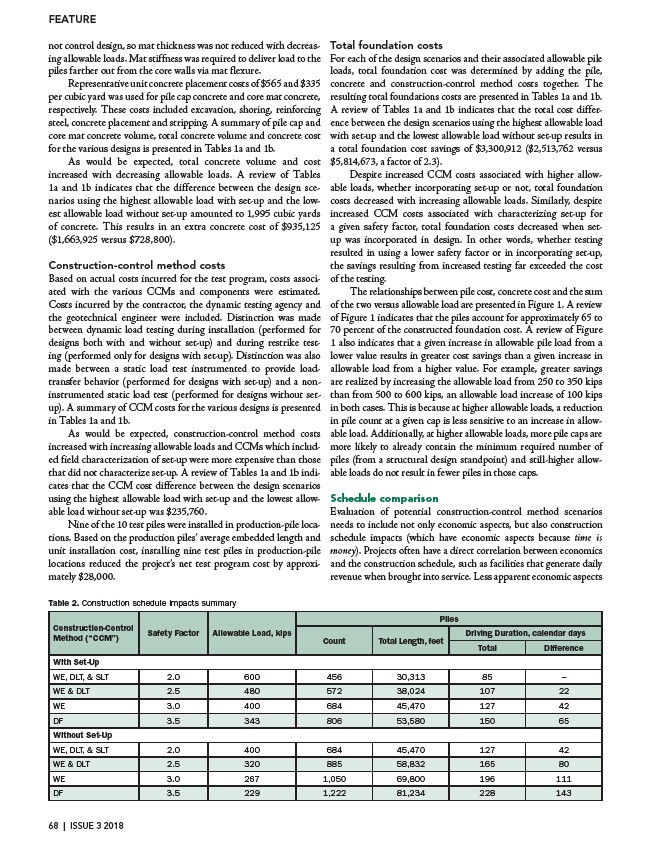

Table 2. Construction schedule impacts summary

Construction-Control

Method (“CCM”)

Safety Factor Allowable Load, kips

Piles

Count Total Length, feet

Driving Duration, calendar days

Total Difference

With Set-Up

WE, DLT, & SLT 2.0 600 456 30,313 85 –

WE & DLT 2.5 480 572 38,024 107 22

WE 3.0 400 684 45,470 127 42

DF 3.5 343 806 53,580 150 65

Without Set-Up

WE, DLT, & SLT 2.0 400 684 45,470 127 42

WE & DLT 2.5 320 885 58,832 165 80

WE 3.0 267 1,050 69,800 196 111

DF 3.5 229 1,222 81,234 228 143

68 | ISSUE 3 2018