FEATURE

from a drivability perspective using readily available equipment.

Ten test piles were installed, driven to near-maximum attainable

end-of-drive capacities. The piles were driven using a Delmag D46

32 single-acting diesel hammer.

To aid in demonstrating even higher capacities, soil set-up

was characterized utilizing relatively long-term restrikes (36 to

54 days after EOID) using an APPLE drop hammer. Set-up

characterization included determining both total set-up magnitude

and distribution along the shaft, allowing set-up to be

incorporated into production-pile driving criteria. Dynamic

monitoring using a Pile Driving Analyzer® (PDA) and subsequent

CAPWAP® analyses were performed on dynamic test

records from all the test piles’ installations and restrikes. Based

on test-program results, it was anticipated that production piles

could be driven to depths at which they would experience a minimum

set-up of 400 kips so that their long-term capacity would

equal or exceed 1,200 kips. Design and construction proceeded

using 600-kip allowable load piles.

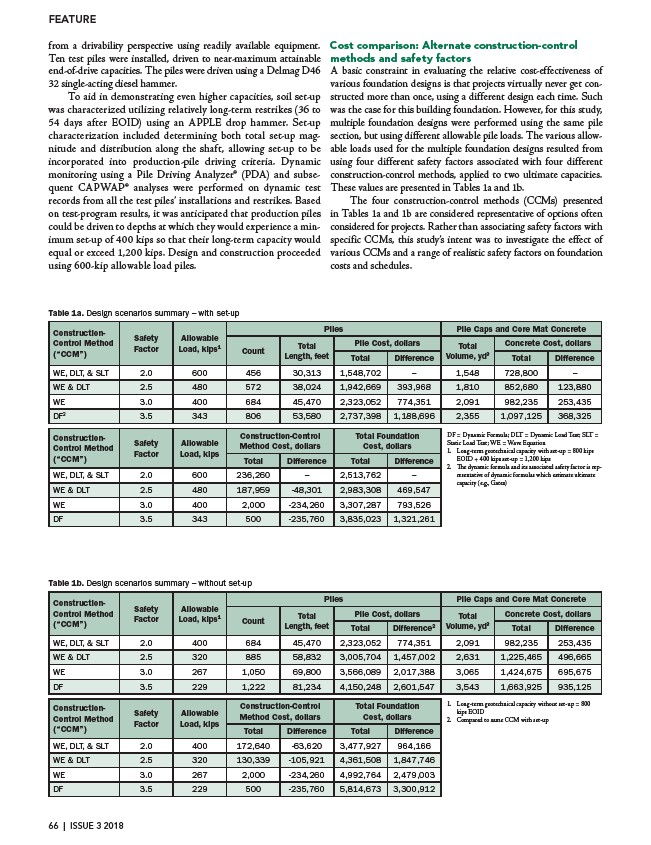

Cost comparison: Alternate construction-control

methods and safety factors

A basic constraint in evaluating the relative cost-effectiveness of

various foundation designs is that projects virtually never get constructed

more than once, using a different design each time. Such

was the case for this building foundation. However, for this study,

multiple foundation designs were performed using the same pile

section, but using different allowable pile loads. The various allowable

loads used for the multiple foundation designs resulted from

using four different safety factors associated with four different

construction-control methods, applied to two ultimate capacities.

These values are presented in Tables 1a and 1b.

The four construction-control methods (CCMs) presented

in Tables 1a and 1b are considered representative of options often

considered for projects. Rather than associating safety factors with

specific CCMs, this study’s intent was to investigate the effect of

various CCMs and a range of realistic safety factors on foundation

costs and schedules.

Table 1a. Design scenarios summary – with set-up

Construction-

Control Method

(“CCM”)

Safety

Factor

Allowable

Load, kips1

Piles Pile Caps and Core Mat Concrete

Count

Total

Length, feet

Pile Cost, dollars Total

Volume, yd3

Concrete Cost, dollars

Total Difference Total Difference

WE, DLT, & SLT 2.0 600 456 30,313 1,548,702 – 1,548 728,800 –

WE & DLT 2.5 480 572 38,024 1,942,669 393,968 1,810 852,680 123,880

WE 3.0 400 684 45,470 2,323,052 774,351 2,091 982,235 253,435

DF2 3.5 343 806 53,580 2,737,398 1,188,696 2,355 1,097,125 368,325

Construction-

Control Method

(“CCM”)

Safety

Factor

Allowable

Load, kips

Construction-Control

Method Cost, dollars

Total Foundation

Cost, dollars

Total Difference Total Difference

WE, DLT, & SLT 2.0 600 236,260 – 2,513,762 –

WE & DLT 2.5 480 187,959 -48,301 2,983,308 469,547

WE 3.0 400 2,000 -234,260 3,307,287 793,526

DF 3.5 343 500 -235,760 3,835,023 1,321,261

DF = Dynamic Formula; DLT = Dynamic Load Test; SLT =

Static Load Test; WE = Wave Equation

1. Long-term geotechnical capacity with set-up = 800 kips

EOID + 400 kips set-up = 1,200 kips

2. The dynamic formula and its associated safety factor is representative

of dynamic formulas which estimate ultimate

capacity (e.g., Gates)

Table 1b. Design scenarios summary – without set-up

Construction-

Control Method

(“CCM”)

Safety

Factor

Allowable

Load, kips1

Piles Pile Caps and Core Mat Concrete

Count

Total

Length, feet

Pile Cost, dollars Total

Volume, yd3

Concrete Cost, dollars

Total Difference2 Total Difference

WE, DLT, & SLT 2.0 400 684 45,470 2,323,052 774,351 2,091 982,235 253,435

WE & DLT 2.5 320 885 58,832 3,005,704 1,457,002 2,631 1,225,465 496,665

WE 3.0 267 1,050 69,800 3,566,089 2,017,388 3,065 1,424,675 695,675

DF 3.5 229 1,222 81,234 4,150,248 2,601,547 3,543 1,663,925 935,125

Construction-

Control Method

(“CCM”)

Safety

Factor

Allowable

Load, kips

Construction-Control

Method Cost, dollars

Total Foundation

Cost, dollars

Total Difference Total Difference

WE, DLT, & SLT 2.0 400 172,640 -63,620 3,477,927 964,166

WE & DLT 2.5 320 130,339 -105,921 4,361,508 1,847,746

WE 3.0 267 2,000 -234,260 4,992,764 2,479,003

DF 3.5 229 500 -235,760 5,814,673 3,300,912

1. Long-term geotechnical capacity without set-up = 800

kips EOID

2. Compared to same CCM with set-up

66 | ISSUE 3 2018